High energy efficiency housing with real and certified industrialisation

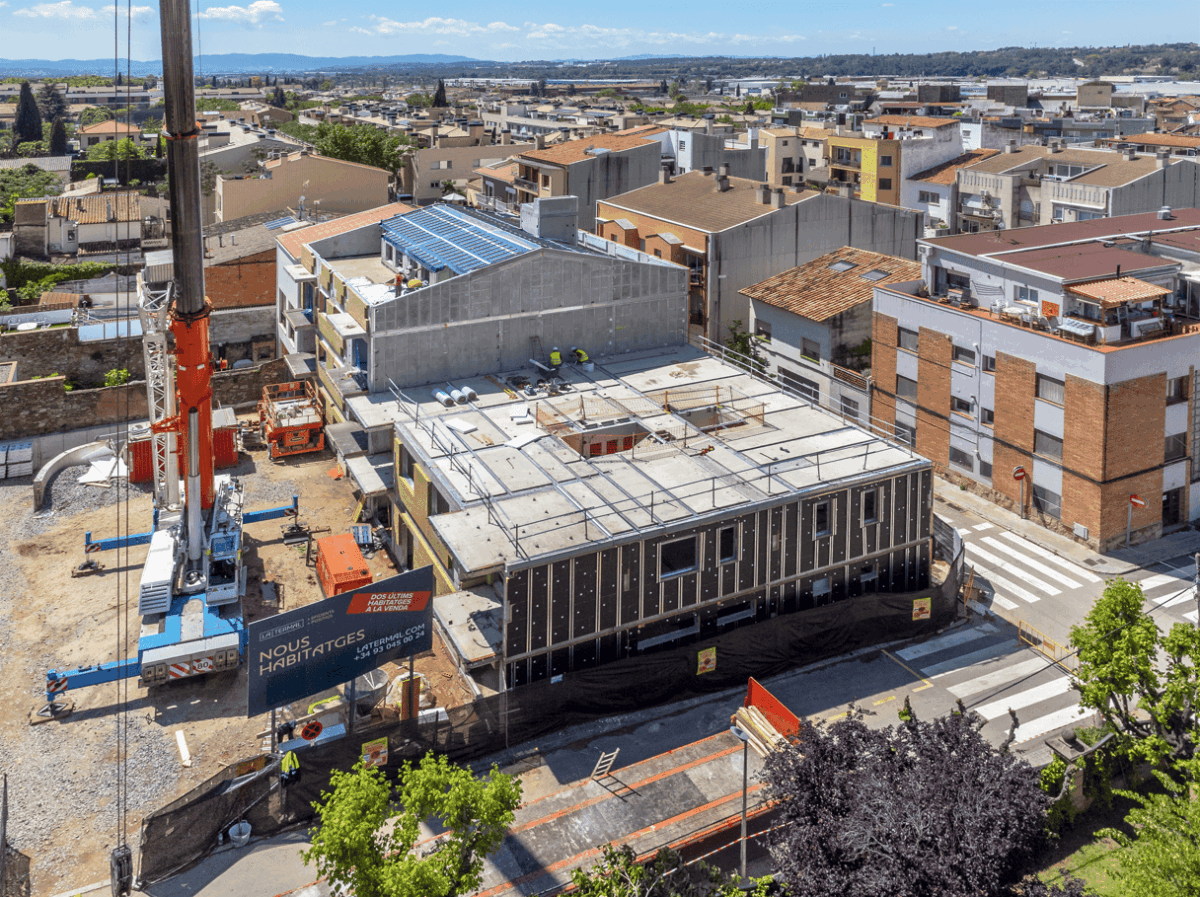

La Termal marks a turning point in the application of the Evowall industrialised system. It is the first multi-family housing development built entirely with our validated and certified Evowall system. The project, executed by Roig Construccions, is located in the urban centre of La Garriga (Barcelona).

The development consists of two buildings with 4 floors each and a total of 14 dwellings. It is not a prototype, but a real project, fully compliant with current regulations and adapted to its urban context. It clearly demonstrates how industrialisation can respond to demanding projects in terms of both design and energy efficiency, as well as comfort.

Passivhaus Plus and positive energy: homes of the future

La Termal has been designed to obtain Passivhaus Plus certification, and thanks to the photovoltaic installation, the buildings can generate more energy than they consume. This makes them positive energy buildings, with minimal environmental impact and maximum comfort for their residents.

This commitment to sustainability has been very well received by the market. 12 of the 14 homes were sold within a few weeks before construction began, and the remaining units were reserved at the start of the assembly. The Evowall system delivers real value: perceived quality, certified sustainability, and a new way of building.

Industrialisation: speed, precision and minimal urban impact

The entire project has been built using Evowall 2D industrialised panels that integrate metal structure, thermal envelope, insulation and service routing. The system was used for external and internal walls, slabs, roofs and stairs, ensuring a continuous and coordinated execution.

The complete assembly of the buildings was completed in just 26 working days, with minimal impact on the urban environment. This speed reduces timelines, indirect costs and on-site risks, improving the economic and environmental feasibility of the project.

A success story recognised by the industry

La Termal is one of four European pilot projects within the REN+HOMES initiative, and one of only two new-build developments. This European project promotes new models for high energy efficiency, low carbon housing, positioning Catalonia as a European benchmark for sustainable construction.

The project has generated significant interest among industry professionals. More than 150 people have visited the site, including developers, architects, builders, public institutions and financial entities. It has also been recognised as a success story by the Industrialised Construction Observatory, highlighting its ability to deliver distinctive value in comfort, sustainability and perceived quality.

With La Termal, Evowall proves that high-quality industrialised construction is not just a promise—it is a reality transforming the sector.

A Passivhaus project made possible through expert collaboration

In our commitment to promote sustainable, efficient and high-quality architecture, we have relied on a multidisciplinary and highly specialised team that made this ambitious Passivhaus project possible. From the design phase to execution, every detail has been carefully handled by leading professionals and suppliers in their fields.

Technical team and main collaborators

• Evowall Technology – Manufacturer of the industrialised construction system, providing speed, energy efficiency and precision.

• Evotecnia Solutions – Company specialised in the assembly and implementation of the Evowall system.

• Roig Construccions – Construction company responsible for carrying out the project to the highest quality standards.

• Hem Green & Balanced Architecture – Architecture studio led by Gemma Blanes and Marina Farró, focused on sustainability, biohabitability and conscious design.

• Oliver Style de Praxis Resilient Buildings – Passivhaus designer who optimised the project to meet the demanding standards.

• Micheel Wassouf de Energiehaus Arquitectos – Passivhaus certifier ensuring compliance with all energy efficiency and comfort requirements.

• Consorci Passivhaus – Platform supporting and promoting construction under the Passivhaus standard in Spain.

Additionally, the project involved leading suppliers offering the most advanced products on the market, essential to achieving the high quality delivered to the final users.

Key suppliers who made technical excellence possible

• Knauf Insulation – Mineral wool insulation for the internal SATE façade system.

• Kingspan Insulation – High-performance thermal insulation with fire resistance for ventilated façades.

• Equitone – Durable exterior finish for the ventilated façade.

• Iso Chemie – High-performance sealing systems for optimal airtightness.

• Deceuninck – High-performance energy-efficient PVC windows, ideal for Passivhaus buildings.

• Zehnder Group – Mechanical ventilation systems with heat recovery, crucial for indoor air quality and thermal comfort.

This project is a clear example of how expert collaboration, technical innovation and a sustainable vision can create spaces that are not only energy-efficient, but also comfortable, healthy and environmentally responsible.